Work in Progress

The GBH Racer at the spray shop

Check back here for pictures of the finished article really soon ! Redline article

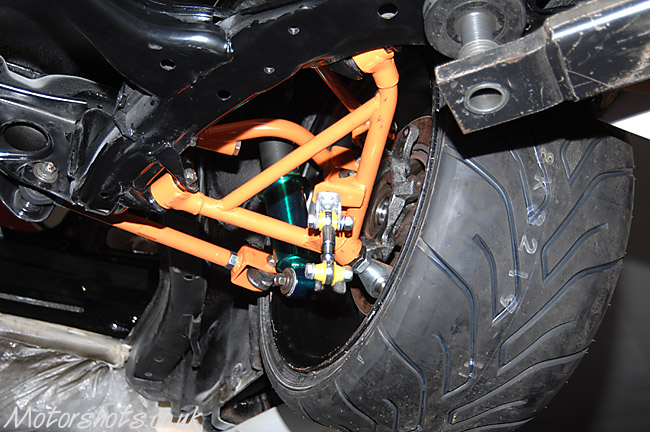

This month the suspension has been centre of attention, which started with freshly powder coated crossbeams and lower arms - followed by a set of Tein coilovers. All the adjustable partshave been well lubricated for ease of adjustment throughout their life. All components were adjusted to equal settings on both left and right to give an equal platform to start initial set up from. With the freshly overhauled hubs in place, they were keen to get those great looking TSW rims and Yokohama rubber on to see how the calculations had worked out with the offset and arch clearance. The sums were perfect and the wheels are sitting just right in the arches. With confirmation that there was nothing to worry about on the wheel front, it was time to do a dummy fit with the seats so that they can work out the positioning of all the driver controls and obligatory fire extinguisher. The car is is to have a custom dash made, again for the driver's position and ease of controls. They're now ready to take mounting bell measurements for the AP discs. The brief on the brakes is to achieve a reasonably cheap system that will perform properly without the need to be too extravagant. The combination of AP discs, GBH bells, Ferodo DS2500 pads, R34 Brembo calipers front and rear, and GBH's own modified master cylinder running through a bias valve and an E brake should enable them to have a brake split from 50:50 to 85:15. Next month it'll be time for a mock engine install so they can work out the transmission placement and take the measurements for the one piece carbon prop...

|